Machines and moulds must be serviced at certain intervals. So that you do not lose track of the work and deadlines involved, the ALS provides support with the maintenance module in which you manage maintenance orders for the production resources. Using the protocolled data as a basis, the ALS announces when maintenance work becomes due.

Creating maintenance orders

To create a maintenance order, open the maintenance module and select the required resource in the tree in the left-hand window.

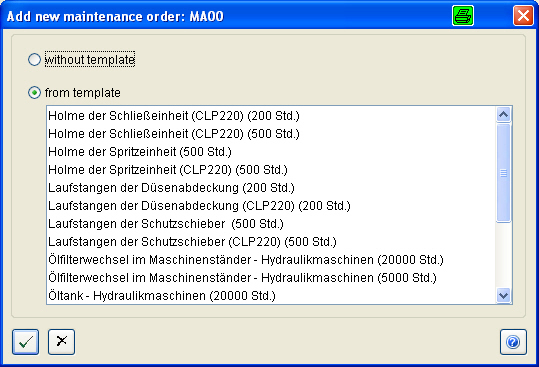

Call up the dialog 'Add new maintenance order'.

Select a template.

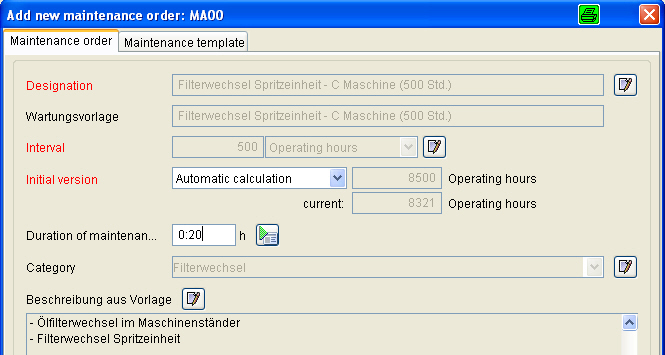

Using templates has the advantage that the same activities are always described in the same way and assigned to the same category. The maintenance orders are directly connected to the templates from which they were created. Changes in the template are thus transferred to the maintenance orders. Additional specifications pertaining to the maintenance order can be entered in the boxed marked 'Additional text'.

With the 'Change value'  icon you have the possibility of editing data taken over from the template. As soon as a specification box is edited the connection to the template

is broken. Next to the edited boxes you will find the icon

icon you have the possibility of editing data taken over from the template. As soon as a specification box is edited the connection to the template

is broken. Next to the edited boxes you will find the icon  with which the connection to the template can be reestablished. On the 'Maintenance template' page

you will find the original data of the template.

with which the connection to the template can be reestablished. On the 'Maintenance template' page

you will find the original data of the template.

What else you should specify is the time of the initial execution. In the 'automatic calculation' mode, the start of the maintenance interval (time between services) is calculated from the time of the initial setting into operation of the resource. For this mode it is important that you input the date of the initial setting into operation when configuring the resource in the ALS. Otherwise the date of the first protocol of the resource is used. In the 'manual specification' mode you specify when the maintenance work is to be carried out for the first time. Additional information can be added in the 'description' box.

Execution of maintenance orders

Which maintenance orders are due for execution is seen in the list of maintenance orders when you select the 'due maintenance orders' branch in the categories. If you activate the option 'due maintenance

orders with pre-warning' and input the remaining operating hours/days, orders which become due in a certain period appear in the list. 'Due' orders are marked with a red square in the respective column. When an order becomes due, a message

is output in the service module under 'messages'. If you sort the 'messages' according to the categories of 'machine' or 'mould' only the messages related to these will be shown. When a message is output, the maintenance

order concerned received the status of 'notified'.

The ALS can be configured in such a way that pre-warnings can be output as general messages at a programmed time in advance. In this case, no special

messages are output.

![]()

| When maintenance work is due on a machine, you generate an inspection order from the maintenance order. This can be scheduled in the plan table so that the machine is inhibited for production orders for the period of maintenance. | |

| The persons responsible for the execution of the maintenance work are informed using the 'Maintenance documents'. Select the due maintenance orders from the list and activate the option 'Maintenance documents of selected orders' in 'Print options'. | |

| When a maintenance order is started, set the status of the order to 'in progress'. Record any particulars required in a 'memo'. | |

| When the maintenance work is completed, tick off the maintenance order with a 'maintenance handshake'. In the 'Maintenance handshake' dialog, the designation of the maintenance order is output under 'Info1'. All available information on this order is found in 'Free text'. When a free-text template is used for this input area, all previous information will be overwritten. If you want to keep any of this information which is not included in the template, copy it into one of the info-boxes. After handshaking the order, the interval counter is reset and the next maintenance interval begins. | |

| You will find the 'handshake' again in the History of the production resource which you access by selecting the relevant production resource and maintenance order and activating the 'machine history' function. |