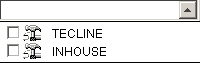

The mould list can be pre-selected according to certain types of moulds or moulds with certain statuses. The icon ![]() in the '

inhibited' column signalises that the mould must currently not be used for production.

in the '

inhibited' column signalises that the mould must currently not be used for production.

| Moulds which are mounted on a machine currently in production are marked with the 'production' status and the name of the machine is given as the current storage location. After strip-down, the status of the mould changes to 'Look over', but the machine remains the current storage location. This has to be changed manually because ALS does not have the required information pertaining to the new storage location or activities to be carried out. |

To add a mould, you must only specify the 'mould’ designation and select the mould type. All other input boxes are pre-assigned with standard values.

The following mould types are currently supported:

Injection mould

Punch mould

The following versions are available

Standard mould

Combination mould

Master

Insert

Accessories

A combination mould is comprised of a master and one or more inserts. The cavity count of a combination mould is derived from the number of cavities

in the inserts. The shot weight is assigned to the combination mould. For combination moulds, the register in the dialog is extended by the page 'combination’. Here you select the master mould and the inserts

to be used.

When 'compiling' a combination mould, rotary table moulds can also be taken into consideration. Here each insert is counted as a station on the rotary table. The number of shots is then divided by the number of stations and

the result allocated to the inserts for purposes of counting cycles for the maintenance interval. This is displayed in the 'Booking' column.

The standard value for the mould status is 'available'. The following values can also be accepted by the status :

locked

prepared

production

checking through

inspection

repair

on trial.

For the statuses 'not available', 'inspection', 'repair' and 'on trial' the input boxes 'to' are active where you can input the time when the mould will be available again.

The control box 'inhibited' indicates whether the mould has been inhibited for current use. This status can be set with the 'Mould inhibit/release' function. The column 'inhibited by' in the mould list tells you which ALS user inhibited the mould

A mould can be assigned to one or more mould groups. New moulds are created in 'Master data' -> 'Infrastructure->groups'.

A mould can be assigned to one or more mould groups. New moulds are created in 'Master data' -> 'Infrastructure->groups'.

Input the 'current storage location' and the 'original storage location' of the mould. The locations which are displayed for selection, are stored under 'master data' -> 'Infrastructure->locations'.

On the 'Dimensions/weights' page you have the possibility of categorising your moulds with a number in the 'machine size' selection field. The values for this selection field originate from the

machine data, where they are input at 'size/category'.

The shot weight is only a guide, as it can vary depending on the material.

In addition to the mould dimensions, you can also input information on a drawing.

The data input at 'maintenance interval' is used as the interval for the execution of general basic work.

You can store a picture together with references to drawings on the mould in the 'Picture' page. The formats 'GIF', 'JPEG', 'PNG' and 'BMP' are supported for the picture. Please note that pictures can only be viewed by all ALS users when they have been stored on a file server to which all ALS users have access.

The 'Additional' information can include 'possible items', which can be produced with the mould as well as the 'possible materials', which can be used for production. In the input boxes you can specify several items or types of material. The date of the 'Initial setting into operation' is used as a basis for calculating the dates when Maintenance orders are to be carried out.

The Document administration ![]() enables you to store further information (e.g. a CAD drawing) on a mould.

enables you to store further information (e.g. a CAD drawing) on a mould.

Note: The mould data stated here are mainly only for information.

In the 'Change mould' dialog all inputs except the 'mould type' can be changed.

When you change the status of a mould, the option of making an entry in the mould history is offered on quitting the dialog.

Status and location changes for a combination mould can also be taken over for the master mould and the inserts. The same applies to the mould history.

You can change the status of a mould in the "Change status" dialog and also specify how long the new status is to be valid. In addition you can specify the current location.

Combination moulds and their components have a selection box in this dialog which you can use to supply information as to whether the mould is 'currently combined'. This box can only be ticked for combination moulds. If, according to ALS, one of the components is currently in use in another mould, that component is rebooked to the 'current' mould.

The 'Mould sheet' report gives you an overview of all available data on a mould. The name of the mould is also displayed as a bar code. With combination moulds consisting of master mould and inserts, you have the option of printing out all the data of the complete mould or only the data of the individual components.

With this icon you delete a selected mould.

Events such as purchase, maintenance, repair, conversion etc. are documented in the 'machine history'. Here you input the date of the event, the operating hours of the machine, text in up to 5 'Info fields' and in a free text area.

(see 'History')

With this function you set the information that the mould is locked (not available). This information is displayed in the columns 'locked' and 'locked by' in the mould list. The symbol ![]() is also output in the report 'Mould - preparation '.

is also output in the report 'Mould - preparation '.

You can 'unlock'

a mould again by calling up the function for a locked mould and reactivating it.

Each time you 'lock' or 'unlock' a mould, the system displays a dialog with which you can make an entry in the 'history' of the mould.

When a 'master mould' or an 'insert' is locked, the respective 'combination mould' is also locked. When the last disabled component of a combination mould is unlocked, the system asks

whether the combination mould can now also be unlocked (enabled).

In the Document administration you can put the various documents on a mould (e.g. CAD drawings, etc.) together with the mould data.

If you have selected a combination mould from the mould list, you can click on this function to call up a list of the components which the mould is comprised of.

This function opens a list of those combination moulds in which the master mould, insert or other accessory are used.

After you have generated a new mould in the ALS, a dialog appears in which you can enter the number of previously completed cycles and operating hours as well as good and bad parts produced.

![]() The dialog may only be carried out once for each means of production. Only the 'ADMIN' user has access to this dialog.

The dialog may only be carried out once for each means of production. Only the 'ADMIN' user has access to this dialog.